Product Identification Specialists

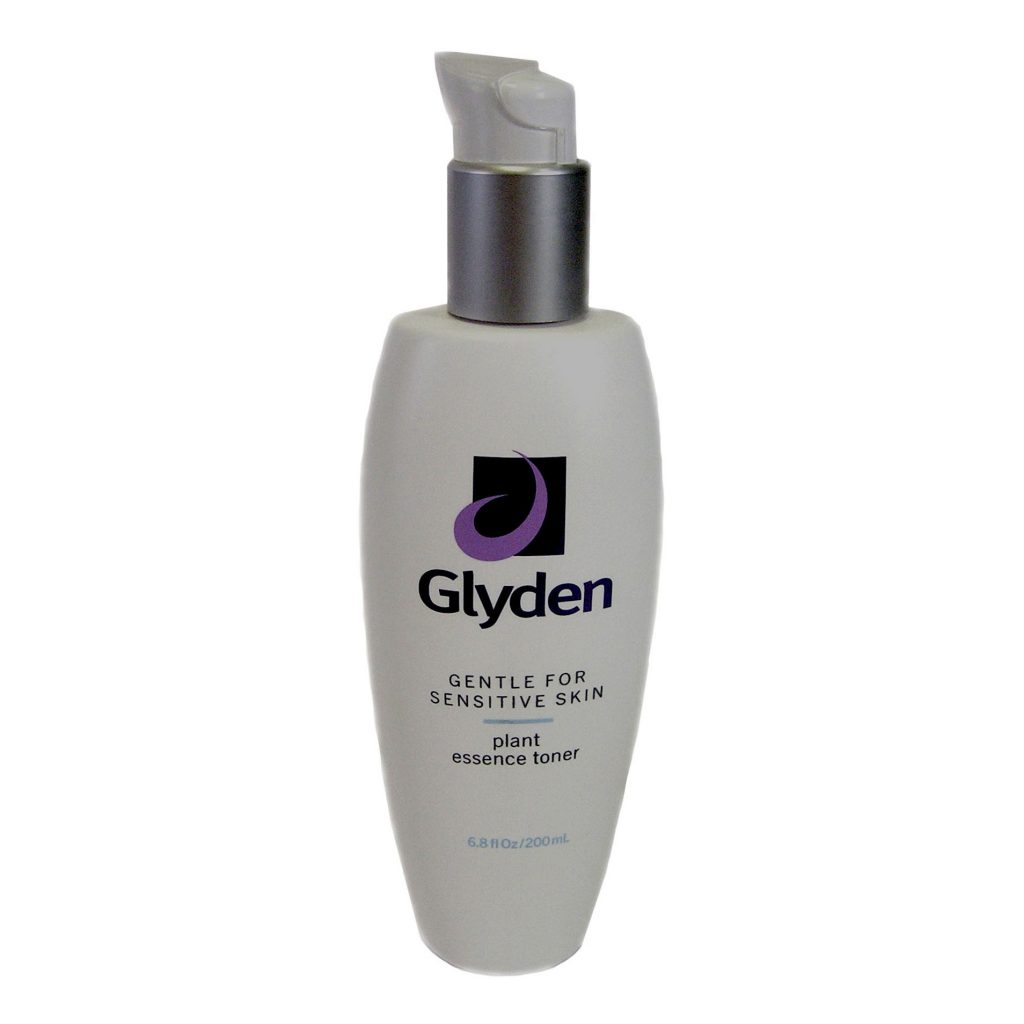

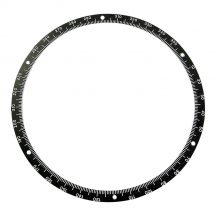

For over five decades, Reichert Corporation’s continued success is based on a commitment to quality work and a broad range of printing capabilities. Our services include computer engraving, pad printing, screen printing, sublimation and digital printing. The diversity of our printing methods gives us the ability to print multiple colors on wood, glass, plastic, bottles, metal and cosmetic products.